Growing Opportunities in Custom fabric designer software

In this digital age, technology has advanced, and most individuals are familiar with digitized procedures. Digital printing technologies are rapidly expanding and improving in the textile printing sector. The textile printing industry has been evolving to incorporate new revolutionary technology such as custom fabric designer software. With advancements in digital fabric printing technology, your customer can now personalize and order unique fabrics from anywhere, at any time, using any device.

Given how much digital technology has already influenced every area of our everyday lives, it is probably not unexpected that the global fashion business is also undergoing its own digital metamorphosis.

By implementing web to print, artificial intelligence, mobile commerce, 3D printing, and blockchain technologies, it is clear that the fashion industry is fast adopting the latest digital technologies and planning for a digital future. In this article you will get to know about the growing opportunities in the fabric and textile industry.

The current scenario of fabric software

The fabric printing machines market has grown significantly in recent years and is projected to maintain its upward trend in the future. This expansion can be ascribed to a variety of factors, including increased demand for customized and printed fabrics in the fashion and garment industries, improvements in digital printing technology, and an increasing number of eco-friendly and sustainable printing technologies.

Furthermore, the increasing customer preference for distinctive and personalized patterns is driving market demand for fabric printing equipment. The future forecast for the fabric printing machines market is positive, with technical advances and innovations projected to drive additional market expansion.

Fabric printing machines are divided into several types depending on their printing procedures in the digital textile industry. Thermal transfer printing machines used heat to transfer designs on fabrics. Digital inkjet printing machines use inkjet technology to print graphics directly into fabrics. Flat screen printing machines use a flat screen to apply ink to materials.

Rotary screen printing machines employ a cylindrical screen to speedily print designs on fabric. Walk the print machines, also known as carousel printers, employ a revolving system to print numerous fabrics at the same time. Other competitors include specialized fabric printers that cater to specific printing needs or use innovative techniques.

Fabric printing machines are widely utilized in many sectors for a variety of applications. In the garment industry, these machines are used to print designs, patterns, and logos on various materials. In the architectural sector, usage of the fabric printing machines are usually used to generate visually appealing and customized fabric artwork for interior decorations.

These machines are used in the advertising industry to print enormous banners, billboards, and other promotional items. Fabric printing machines are also utilized in various industries, such as interior design, automotive, and healthcare, to create and print fabrics. Also the usage and implementation of custom fabric designer software’s have proved to be very significant.

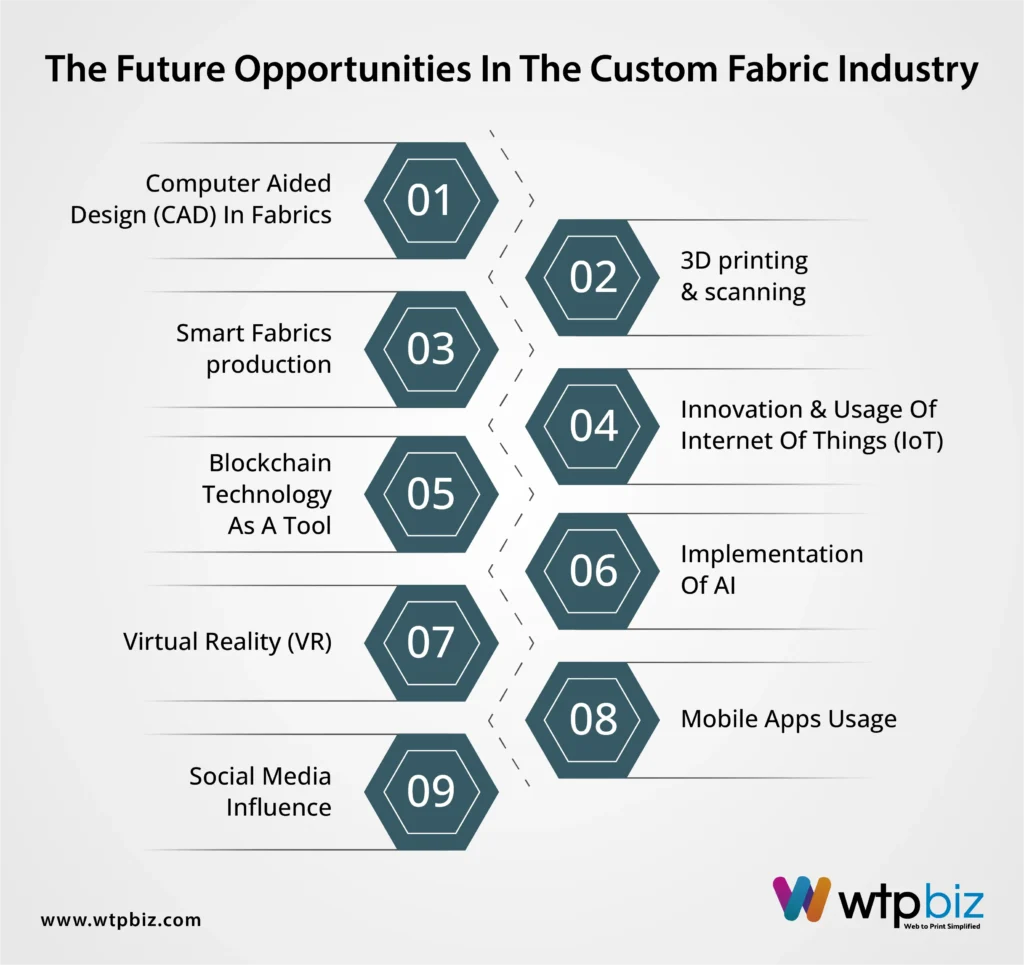

The future opportunities in the custom fabric industry

Computer Aided Design (CAD) in fabrics

Today’s fashion designers can utilize powerful software to visualize their ideas on a computer screen before putting them into mass production. Initially, the use of CAD for fashion design expanded from scanning existing textile patterns to readily creating new and distinctive patterns. Not only does CAD increase a fashion designer’s efficiency, but it also increases the overall quality of the design. Accurate and efficient, CAD also serves as a manufacturing database, allowing designers to create and implement new concepts much faster.

3-D printing and scanning

Many worldwide fashion firms have embraced advances in 3D printing technology to provide their customers with everything from accessories to designer clothing. Most importantly, by pioneering new techniques of customization and sustainability, 3D-printing garments on demand reduces fabric waste.

Furthermore, 3D scanning software enables designers and manufacturers to construct clothing based on precise body measurements and proportions, resulting in clothes that fit flawlessly. Fashion designers benefit from tech that allows them to virtually evaluate how garments will look on specific body types.

Smart Fabrics production

Simply said, smart materials could be the finest answer for creating a future that is more environmentally friendly for the global fashion sector. Have you ever wanted a shirt that will keep you cool in the summer and toasty in the winter? Consider a t-shirt that changes colour based on your mood, ambient lighting, or when you receive an email.

Tech behemoths are already developing touch-responsive fabrics consisting of conductive threads that will change colour in response to emotions, user settings, and temperature. Smart materials will eventually revolutionise ordinary clothing.

Innovation and usage of the Internet of Things (IoT)

The Internet of Things (IoT) is one of the most intriguing technological innovations, with the potential to significantly revolutionise the fashion sector. From smart watches to responsive sportswear, multi-function designs, and even smart clothes, brands are essentially creating networked wearable devices that can communicate data via the internet.

Amazing examples that are now available are smart socks that can track your steps and calories, as well as powered suits that can react to a user’s natural movements, strengthening muscle power and providing strength for getting up, sitting down, or staying upright.

Blockchain Technology as a tool

Blockchain technology has revolutionized supply networks in a variety of industries. It is the most effective digital instrument for ensuring supply chain transparency, traceability, and efficiency for all stakeholders involved. Everyone, including banks, carriers, and middlemen, can connect directly and securely and gain access to crucial vital data.

Implementation of AI

AI can provide fashion companies with a variety of competitive benefits, ranging from customer service chatbots to trend forecasting and supply chain management. Automated versioning is another fascinating use that has enormous promise for fashion shops. This is an AI and machine learning technique that can generate many versions of a single human model, allowing for the creation of virtual fitting rooms, decreasing waste and returns, and providing customers with greater ease and accuracy.

Virtual reality (VR)

Fashion businesses have employed virtual reality to integrate the online and physical worlds of retailing. In its most practical application, VR technology allows internet customers to virtually try on numerous clothing before making a purchase.

Its outstanding accuracy and customised measuring functionality allow clients to efficiently try and buy numerous products even when they are not available in a real store. Furthermore, VR may be utilised to provide customers with 3D and 360-degree shopping experiences, essentially virtual stores, which are easily accessible via brand websites, mobile applications, and social media platforms.

Mobile apps usage

Mobile commerce, often known as mobile shopping, is one of the e-commerce industry’s fastest growing industries. As consumers take use of ever-improving smartphones and digital payment solutions such as Apple and Android Pay, it has never been easier to buy practically anything on the move using a mobile device.

Social media influence

Furthermore, with social media platforms fundamentally altering the way we engage with both individuals and businesses, fashion firms can now maintain a strong presence on all of their clients’ preferred online channels, producing unprecedented brand visibility and expanding sales prospects. Sustainable fashion applications such as Depop and Vinted specialise in second-hand apparel sales.

Conclusion

With an increasing number of digital textile printing solutions on the market, as well as their high quality, affordability, and ease of use, entrepreneurs have more opportunities to enter the market, start their own businesses, and provide unique services to their brand and designer clients.

Many industries have seen a significant increase in economic growth since fully embracing digitization and also implemented custom fabric printing. The fashion and apparel business is also undergoing a digital shift. Technologies such as 3D prototyping, digital fashion design programmes, digital avatars, and virtual showrooms are reshaping the new digital revolution.

With more and more businesses implementing digital processes, manufacturers and retailers are likewise adopting technological media to improve their fashion supply chain operations.

Earlier clothes were created from pen-and-paper sketches, which were then converted into tangible examples using hand-cut paper patterns. The situation has altered with customisable fashion design software, which enables designers to exercise their creative freedom and produce dynamic design lines.

Brands and retailers are using more realistic 3D sample designs to develop and manufacture clothes more efficiently. As a result, brands have chosen increasing levels of digitalization to optimise both their production and supply chain processes. So based on the current trends of digitalisation, you may implement the usage of custom fabric designer software.