Sticker Printing Trends: What’s ahead in 2024

The ultimate goal of any firm is to achieve success and profitability. However, due to the industry’s competitive character, it is difficult to achieve sustained growth. The employment of marketing strategies and tactics is one factor that helps organizations flourish. Similarly, if you are beginning your own business, you must devise strategies to assure its survival and growth.

One thing you’ll learn quickly is how to properly manage your finances. Although this is not the case for everyone, small firms frequently operate on tighter budgets. Knowing how to allocate your limited cash will be critical to your future operations. Stickers are a wonderful place to start when developing your advertising efforts. This is where the Sticker Printing industry is facing a lot of new trends in 2024, which are discussed here.

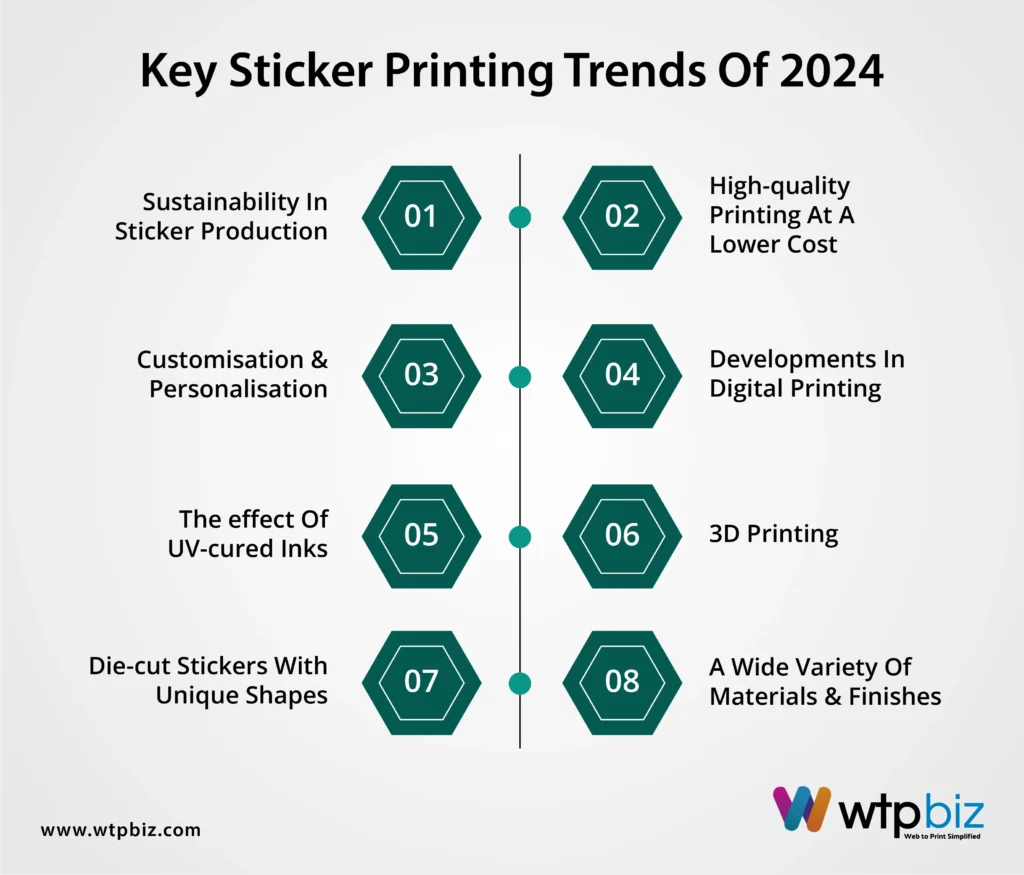

Key sticker printing trends of 2024

Sustainability in Sticker Production

The global movement for sustainability has resulted in the adoption of biodegradable paper, recycled plastics, and plant-based adhesives as the new Sticker Printing standards. These materials provide a safer alternative to typical sticker components, which are frequently made from nonrenewable resources and contribute to environmental deterioration. For example, biodegradable papers degrade naturally without leaving harmful residues, whereas recycled plastics provide new life to items that would otherwise wind up in landfills.

High-quality printing at a lower cost

Digital printing technology, including inkjet and laser printers, have transformed the way stickers are made. These printers can handle a wide range of materials, from traditional vinyl to environmentally friendly paper, allowing for a wide range of sticker applications. One of the most remarkable breakthroughs is the ability to make small runs of high-quality stickers for a fraction of the cost previously associated with large-scale printing processes. This democratization of the sticker printing business has allowed even the smallest firms to obtain professional-grade stickers for branding and marketing purposes.

Customization and Personalization

Digital printing excels at customization and personalization with new sticker designer tools. Modern printers have remarkable flexibility, allowing for the manufacturing of stickers in any shape, size, or design. This potential has resulted in a spike in personalized stickers, which are now being used for anything from wedding favors to corporate branding initiatives. The capacity to swiftly and simply create customized stickers has become a game changer, as businesses seek new methods to stand out and fascinate their consumers.

Developments in digital printing

UV-cured inks and 3D printing technology are two of the most intriguing new breakthroughs in digital Sticker Printing. UV-cured inks are known for their long-lasting properties and brilliant colors, making them excellent for stickers that must survive tough situations such as outdoor use or chemical exposure. On the other side, 3D printing is pushing the boundaries of sticker design, enabling the development of stickers with previously imagined textures and physical qualities.

The effect of UV-cured inks

UV-cured inks have revolutionized sticker printing. These inks cure instantaneously under UV light, producing prints that are resistant to discoloration, water, and abrasion. This makes UV-cured stickers ideal for applications requiring high durability, such as vehicle stickers, outdoor labels, and safety signage.

3D Printing

sticker printing business is taking on a new dimension thanks to 3D printing. This technique permits the creation of stickers with raised surfaces, providing a tactile sensation that can increase brand engagement. Consider feeling the logo on a laptop sticker or the texture on a premium product label. These tactile aspects can greatly increase the sticker’s impact, thereby rendering it more memorable to the consumer.

Die-cut Stickers with Unique Shapes

Die-cut technology has transformed sticker designer creation, allowing you to produce custom stickers in any shape, from simple circles to detailed personalized designs. This level of customization enables businesses to produce visually appealing stickers that closely match their logo and product forms, improving the overall appearance and making the brand more remembered. Die-cut stickers are particularly popular in businesses where branding must stand out.

A wide variety of materials and finishes

Today’s sticker industry offers a wide range of materials, including long-lasting vinyl, flexible polyester, and environmentally friendly biodegradable solutions. Each material has its own set of features that cater to certain needs such as weather resistance, flexibility, and environmental sustainability. The finishes offered, such as matte, glossy, and metallic, add another degree of customization, allowing firms to choose the style that best suits their identity. Matte finishes are ideal for a classy, subtle style, whilst glossy finishes highlight colors and draw attention. Metallic finishes have a premium feel, making them perfect for high-end products and branding. All this is possible with the usage of sticker design tool.

The future of sticker industry

The Sticker Printing industry has seen rapid developments and adjustments towards more environmentally friendly, customizable, and inventive techniques. The development reflects a stronger relationship with the ideals of today’s consumers, as well as a global push for sustainability and personalization.

The changing trends of sticker uses and sticker design tool demonstrates the expanding significance of stickers in marketing, branding, and functional roles. As businesses continue to seek unique and inventive methods to use stickers, we can anticipate even more exciting innovations in this area.

Whether it’s improving real products with digital interactions or utilizing stickers to make a statement in guerilla marketing campaigns, stickers’ versatility is limitless. With continual developments in printing technology and materials, the future of stickers appears bright, with limitless possibilities for both businesses and consumers alike.

Conclusion

As we look ahead, the Sticker Printing sector is prepared for even more developments. The integration of digital technologies, such as augmented reality and smart labeling, is poised to alter the user experience by providing dynamic and immersive brand engagements. The continuous emphasis on sustainability is likely to drive greater innovation in materials and techniques, making eco-friendly stickers the norm rather than the exception.

In this ever-changing context, firms who want to use stickers in their marketing campaigns must be both informed and agile. Sticker printing business that connects with the trends of customisation, sustainability, and technological innovation can not only improve their brand visibility but also positively contribute to the global shift regarding a more sustainable and consumer-centric marketplace.

If you want the latest tool and technology for making the stickers, with the usage of web to print, with WTPBiz now it is all possible.